Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a commonly used thin-film deposition technique in the semiconductor industry. This technology combines the basic principles of chemical vapor deposition (CVD) with plasma technology to produce high-quality thin films with precise control over their properties. Unlike traditional CVD technology, PECVD uses plasma to enhance deposition efficiency, enabling material deposition at lower temperatures.

The relationship between RF power supplies(RF Generator) and PECVD

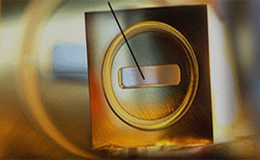

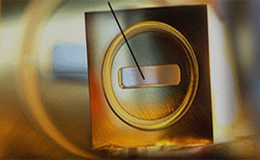

The RF power supply(RF Generator) is the core component of PECVD thin film deposition equipment, providing a stable RF source to generate glow discharge plasma.

Compared to traditional CVD equipment, PECVD equipment forms high-density, high-performance thin films at relatively low reaction temperatures without damaging existing thin films or pre-formed underlying circuits, achieving faster thin film deposition speeds. It is the most widely used type of equipment in thin film deposition processes for chip manufacturing. This technology operates at low pressure, utilising low-temperature plasma to generate glow discharge on the cathode within the process chamber, and using the glow discharge to heat the wafer to a predetermined temperature.

Then, an appropriate amount of process gas is introduced. These gases undergo a series of chemical reactions and plasma reactions, ultimately forming a solid-state thin film on the wafer surface. During the reaction process, the reaction gases enter the furnace chamber through the inlet, gradually diffuse to the wafer surface, and are decomposed into electrons, ions, and active radicals under the influence of the electric field generated by the RF power supply. Specifically: PECVD is typically performed in a vacuum chamber, with parallel trays spaced several inches apart inside the chamber. The silicon wafers are placed on the trays, and RF power is applied to the upper electrodes. When the feed gas flows through the gas main unit and the deposition chamber, plasma is generated, and excess gas is vented around the lower electrode. Sometimes, the reaction gas is introduced around the lower electrode and vented from the centre of the electrode.

Higher RF power increases ion bombardment energy, which improves film deposition quality. Increasing the power enhances the concentration of free radicals in the gas, thereby increasing the deposition rate. However, when the power reaches a certain level, the reaction gas becomes fully ionised, and the free radicals reach saturation, causing the deposition rate to stabilise.

The WATTSINE RF power supply(RF Generator) series features a fully digital design, enabling high stability and reliability of output power through rapid frequency adjustment. It can be quickly configured to meet various customer requirements.

About

Chengdu Wattsine Electronic Technology Co.,Ltd is a national high-tech enterprise located in Chengdu, China, focusing on the application of microwave/RF and high-frequency power energy, engaged in R&D, production and sales of solid-state power generators based on semiconductor devices and high-frequency, high-power technology, provides solutions and technical services for RF energy applications in ISM field.

Products

Applications

In the semiconductor field, Wattsine power generators are one of the key components of the front-end process machines for thin film deposition, etching, ion implantation and cleaning.

Photovoltaic is one of the core areas in the construction of new energy power generation, RF power generators of Wattsine have been widely used in it

power generators of Wattsine have been widely used in the field of particle accelerators, mainly including synchrotron light sources, XFEL, CIADS and others.

Wattsine microwave power generator can be used in the preparation of carbon-based materials, including CVD diamonds, industrial abrasives and tools, diamond thermal conduction and heat dissipation materials, diamond optical window materials and os.

Wattsine microwave power generator can be used in the medical field, mainly in medical accelerators, ablation, thermotherapy, microwave physiotherapy, plasma beauty and others

Wattsine microwave sources (microwave generators) are suitable for industrial applications, mainly in microwave heating, microwave drying, microwave blanching, microwave defrosting, microwave lighting, microwave curing, microwave sintering, and other areas.

News

![]()

![]()

Wattsine News channel provides real-time updates on Wattsine announcements, honors and latest events.

Industry information channel mainly updates the latest international and domestic industry information related to Wattsine products.

CVD Encyclopedia

Industry Encyclopaedia

Support

Chengdu Wattsine electronic to provide a full range of pre-sales service, for you to solve all the concerns related to our products... Pre-sales hotline 028-85964177

All our customers will experience the high-quality after-sales service provided by WATTSINE after purchase our products...

Here you will find a collection of Frequently Asked Questions (FAQs) about our products before and after the sale of Wattsine...

Related videos about Wattsine