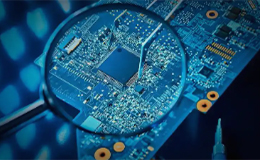

As a stable crystalline form of carbon, diamond possesses high thermal conductivity and a low coefficient of thermal expansion, conferring significant advantages in thermal management applications. Various research findings demonstrate that diamond exhibits markedly superior thermal performance compared to semiconductor materials such as silicon (Si), silicon carbide (SiC), and gallium nitride (GaN). For instance, diamond exhibits a thermal conductivity of up to 2200 W/m·K, exceeding that of silicon by more than tenfold. Compared to GaN, diamond demonstrates superior carrier mobility and breakdown electric field characteristics.Consequently, diamond is unquestionably an ideal heat sink material, capable of significantly enhancing the thermal dissipation capabilities of semiconductor devices. This has now gained widespread recognition within the industry as one of the future thermal management solutions.

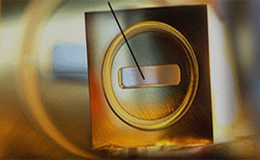

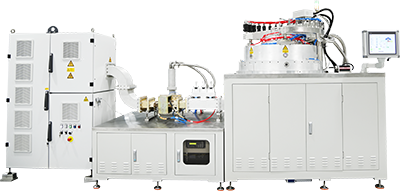

To advance the large-scale application of diamond thermal conduction components and heat dissipation materials, addressing issues of growth rate and film quality while reducing the energy consumption and manufacturing costs of preparation equipment has become an urgent engineering challenge. In recent years, chemical vapour deposition (CVD) technology has advanced rapidly and is now extensively employed for diamond film growth. Among these techniques, microwave plasma chemical vapour deposition (MPCVD) has garnered significant attention due to its suitability for synthesising high-grade polycrystalline and single-crystal diamond films.